Realise the range of benefits

Your tape can be customised into bespoke designs to fit precisely and easily into your product

Your tape can be customised into bespoke designs to fit precisely and easily into your product

We’ve shared the many benefits of using adhesive tapes for your joining needs, but how do you manufacture your products using a roll of tape? Answer: Your tape can be customised into unique designs to fit precisely and easily into your product and processes. Picture supplied by Parafix

Why customise my tape?

Flexible and sticky adhesive tape products can be difficult to work with. Converting your material into a bespoke component makes it easier to handle and apply.

Additional benefits:

- Flexibility in your product design

- Countless shapes and sizes can be created

- Unique structures can be created by combining complementary materials for added functionality

- Consistency in quality of components

- Consistency in placement of parts

- Cost savings from reduced waste

- Cost savings from reduced assembly times.

How can I have my tape customised?

Adhesive materials are customised by tape converters who offer a range of design, cutting and finishing capabilities. With your tape, they can:

- Slit your material to a variety of widths and lengths

- Die-cut your material into any shape

- Combine (laminate) your material with complimentary materials for added functionality, e.g. bond and seal with a foam and adhesive

- Present your final die-cut shapes in a convenient format for ease of application.

Learn more about tape-converting capabilities or find a converter in Afera’s member directory.

Tape it or screw it? Tapes and films are replacing mechanical fasteners

Designers and engineers often turn to traditional fixings, such as rivets, screws, nuts, bolts, staples, clips, needle and thread, and liquid adhesives to join two substrates. Many are discovering however that adhesive tapes and films are proven alternatives to these methods, matching and often exceeding traditional fastenings in strength and durability. Furthermore, they provide unique benefits not found in traditional fastening methods, such as sealing, dampening, shielding and insulating.

|

|

|

Tapes often make your design possible

Tapes can perform a variety of functions at once, meaning that your products could be made thinner, lighter and using fewer and less expensive materials. Tapes and films bring design options to the table that weren’t even conceivable a few years ago. And what’s more, tape can be incorporated into product manufacturing and processing with reliable, reproducible and cost-effective results.

Innovative product design

Tapes offer a unique and sophisticated attachment method that is revolutionising product design. The considerable expertise behind today’s adhesive tapes, as well as the astoundingly wide variety of applications they have, is the constant buzz in product innovation circles. High-quality tapes and films offer versatility and superior workability to designers, engineers and manufacturers in every conceivable industry. They can be specifically designed for any product or application and die-cut into complex shapes.

Here are just a few of the advantages of tapes and films in product design:

- New design freedom and options

- Use lighter, thinner materials

- Improve appearance

- Bond dissimilar materials

- Cheaper prototyping in the early stages of design

- Compare fixing and joining methods

- Creativity and efficiency

Enhanced product performance

Using a tape in place of traditional fixing methods will improve the overall quality and performance of your product by providing a durable bond, even in the most demanding applications. Picture supplied by Nitto

Adhesive tapes and films offer many types of bonding, ranging from repositionable to permanent high strength with the capability of replacing rivets and welds. Tapes allow for reliable, consistent bonds that are not often possible using other techniques. Some automotive tapes used to bond hood emblems to the exterior of the car, for example, are more than a hundred times stronger than household wrapping tape. Some double-sided tapes, depending on the substrate, can offer a bond strong enough to take the weight of a full-grown person. Here are some of the ways in which products are improved by the use of tapes and films:

- Durability and reliability

- Bond and seal, insulate, support, shield and/or conduct simultaneously

- Uniform stress distribution

- Vibration damping and noise control

Manufacturing efficiencies

Using a tape in place of traditional fixing methods can generate efficiencies in your manufacturing processes by reducing costs, enhancing productivity and contributing to a better work environment. Here are some of the advantages of incorporating tapes and films into production:

- Eliminate drilling and reduce assembly time and rework

Save time and money and eliminate the tools and manufacturing equipment required for drilling and tightening. The use of tapes is easily integrated into your operations and in most cases requires minimal training and little or no investment in equipment. Whether handling by hand or with automated equipment, tapes are generally quicker and safer to apply, in often minimising safety risks to operators.

- Minimise adhesive waste and handle immediately

Adhesive tapes provide uniform thickness throughout the bonding area of your product, and clean bonding – both permanent and temporary – in which the adhesive is confined to the bonding area without dripping or overflow, minimising adhesive waste. Adhesive tapes also enable immediate handling of your product as tapes bond rapidly, unlike many liquid adhesives. Reduce finishing and other steps requiring more energy, labour and time. Not only are operations streamlined from eliminating welding and grinding, but using tapes will save the time and cost of refinishing burn marks.

- Disassemble parts easily, if necessary

Reclosable adhesive tape systems allow parts to be separated for easy maintenance or service. Permanent adhesive tapes can be formulated to stay on a specific surface when removed for recycling purposes when the product is dismantled.

Sustainable solutions

The use of any kind of adhesive tape, when compared to an alternative fixing solution, could improve the ecological footprint of your product. Certain tape products have been developed that are environmentally benign or considered as leveraging the environmental friendliness of products. These include water-based and 100% solids tapes, low or no VOC adhesive tapes, solvent-free tapes made without organic solvents or toxic chemicals, and repulpable tapes.

Durability and reliability

Adhesive tapes are used in a wide variety of environmentally challenging applications because they have been proven to resist stress corrosion, cracking and distortion when exposed to extreme temperatures and weather, UV and chemicals. This keeps your product looking younger for longer. Enhanced quality and life span means reduced returns and complaints, saving you money and contributing to a quality reputation.

Bond and seal, insulate, support, shield and/or conduct simultaneously

Continuous contact between surfaces bonded with tape helps keep out water, moisture, dust and other environmental factors. This additional sealing functionality reliably protects the internal parts of your product for a longer life. Tapes have also been developed to provide reliable insulation, mechanical support, aesthetic finishing, point-to-point electrical contact, grounding and EMI (electronics metal finishing) shielding.

Picture: Bond and seal underwater camera housing with die-cut tape. Supplied by Parafix

Uniform stress distribution

Spot welds, rivets, screws, nails and other mechanical fasteners create single-joint stress points. Because the entire force is concentrated on one joint, this attachment can often fail and/or cause material breakage. Bonding tapes distribute stress evenly over the entire bonded area. Double-sided tapes are perfect for tension compensation.

By using tape, you can eliminate stress concentration that decreases substrate integrity. At the same time, get rid of the need for holes that invite rust and corrosion. Your products are stronger and longer-lasting.

Picture supplied by 3M

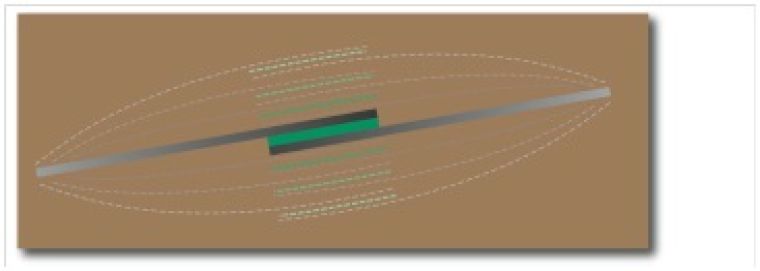

Vibration damping and noise control

The viscoelasticity of many tapes improves resistance to vibration fatigue by adding flexibility to a joint or bonded area. They absorb and dissipate vibration and reduce noise and fatigue.

Creating a product which is protected against vibration and other concentrated stresses is every designer and manufacturer’s aim. Better products mean fewer complaints and product returns, saving on administration and replacement costs.

Picture supplied by 3M